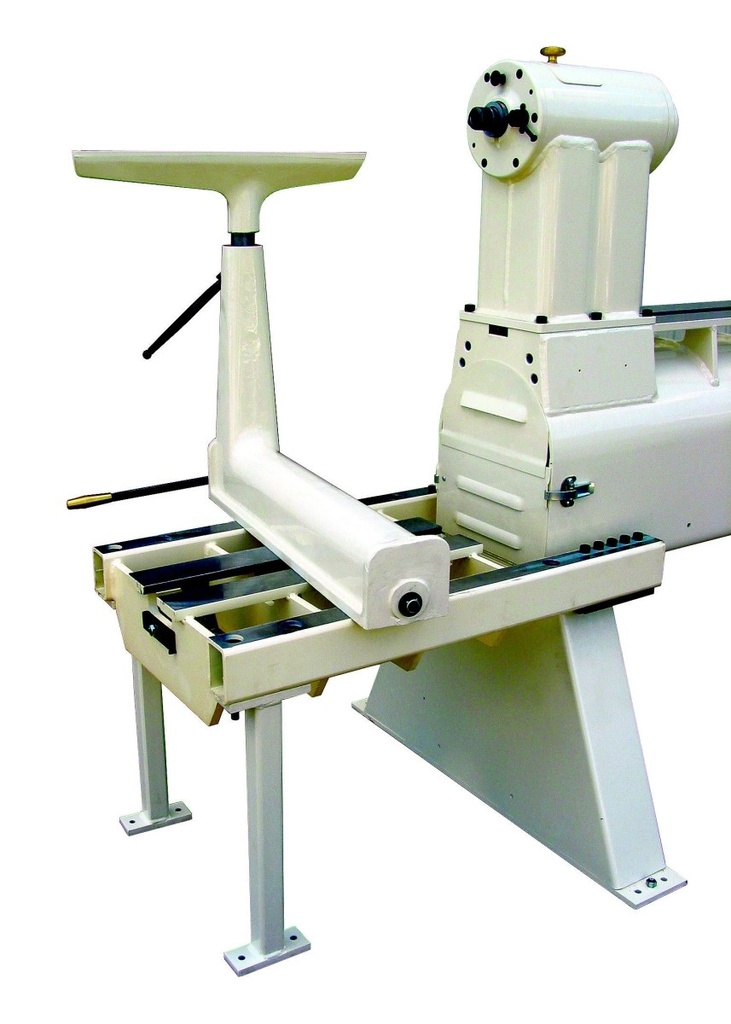

Oneway 2436

Oneway 2436 – Absolute Top Class

The Oneway 2436 is without a doubt one of the very best lathes in the world. A perfect combination of power, design, and user-friendliness. This machine has been manufactured since 1990 by the Canadian company Oneway. Designed for woodturners who want the very best. A lathe for life.

Key Features of the Oneway 2436:

- Center height: 30 cm

- Spindle thread: M33 x 3.5 mm (both inboard and outboard, DIN 800)

- Headstock: Morse taper #2, 48 indexing positions

- Tailstock: Morse taper #3, quill travel 12 cm

- Motor: 3 HP (2.2 kW), frequency-controlled

- Speeds: 70–700 / 190–1900 / 305–3050 RPM (infinitely variable, forward and reverse)

- Spindle: 51 mm diameter, 40 cm long, 16 mm through-hole

The Spindle – The Backbone of the 2436

- 51 mm diameter, 40 cm length, with a 16 mm through-hole

- Made from fully hardened, high-alloy steel with an incredible tolerance of 0.0001 mm (!)

- Runs on four bearings: two massive 45 mm bearings at the front, and two 40 mm bearings at the rear

- Maintenance-free and permanently lubricated

- Equipped with a groove for an Anti-Spindle-Release ring (ASR) – safe to use in both forward and reverse rotation

- The drive runs via three pulleys with a 10-groove Poly V-belt. Should the belt ever fail, it can be replaced in under 15 minutes.

The Headstock

The front of the headstock extends 8 cm, providing extra clearance for bowl turning or reverse-mounted work. The M33 x 3.5 mm spindle thread together with the ASR groove ensures safe and versatile turning in both directions.

The Tailstock

- Made from cast iron, with internal components of tough, hardened steel

- Quill travel: 12 cm, through-bored (8 mm)

- Morse taper #3 for maximum rigidity

- Fast and smooth travel thanks to a trapezoidal lead screw combined with a large handwheel

- Unique clamping system: absolutely zero play when locked

- Convenient rear handle to easily pull the tailstock away from the workpiece

Banjo and Toolrest

- The banjo features a patented lever clamp, no wrench required — reposition quickly and effortlessly

- Widely regarded as the best banjo on the market — even purchased separately by owners of other brands

- The 1-inch toolrest post locks exceptionally securely while still being smooth and easy to adjust — even after a full day of heavy turning

Variable Speed Control

- Speed range from 70 to 3050 RPM, forward and reverse

- Full torque available from just 100 RPM, thanks to the powerful 3-phase motor

- Change between the three pulley ranges in seconds

- The frequency inverter delivers up to 150% peak power for short bursts

- Automatic shutdown protects the motor from overload or short circuit

The Bed – Exceptionally Stiff and Precise

- Constructed from a massive steel tube with welded reinforcement ribs

- The entire frame is stress-relieved and precision ground perfectly flat

- Stiffer than cast iron, offering unmatched precision and vibration-free performance

Included with the lathe:

- 15 cm (6") faceplate

- MC3 live center

- MC2 safe center

- 30 cm (12") toolrest

- Knock-out bar

- User manual (English)

Optional accessories:

Flexible in Size – 4 Versions Available:

There are three other versions of this lathe available:

| Model | Diameter | Between centers | Total length | Weight |

|---|---|---|---|---|

| 2436 | 24" (61 cm) | 36" (91 cm) | 60" (152 cm) | 350 kg |

| 2416 | 24" (61 cm) | 16" (40 cm) | 40" (102 cm) | 300 kg |

| 2036 | 20" (51 cm) | 36" (91 cm) | 60" (152 cm) | 300 kg |

| 2016 | 20" (51 cm) | 16" (40 cm) | 40" (102 cm) | 275 kg |

Oneway 2436 – No Compromises

Want the very best the market has to offer? The Oneway 2436 is the absolute standard. Come and see it — and experience it — for yourself in our workshop!