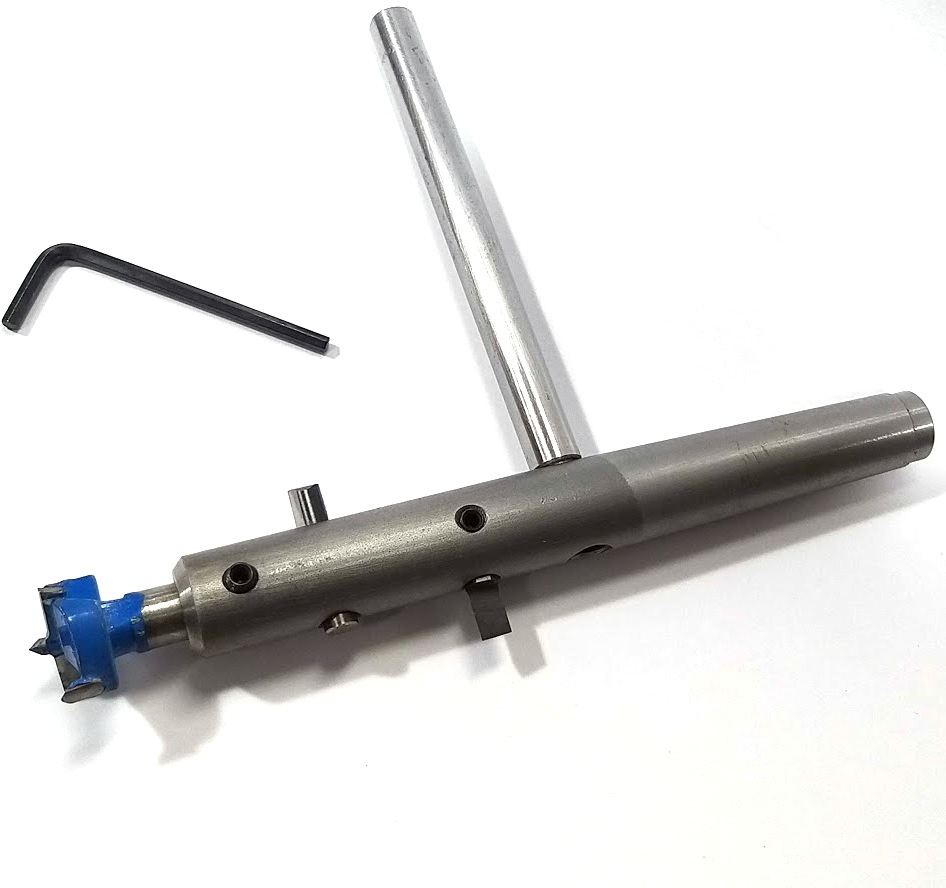

Mini CrushGrind Drill

With this drill you can quickly drill the holes for the Crushgrind Mini Grinders. With 1 drill 3 diameters, look ... that is going fast!

Purpose

This MCB (Mini CrushGrind Drill) is specifically made for the Mini CrushGrind mechanisms. The drill is suitable for use on any lathe with a Morse Taper 2 holder in the tailstock. And the drill is ready for use from the packaging.

Included is:

body of the drill with a Morse Taper 2

2 hardened HSS knives

25 mm drill bit

support rod

hexagon wrench 2,5 mm

instructions

Use

Make sure the headstock and tailstock are in line. Take a suitable piece of wood, turn it round and clamp it in a chuck. Flatten the surface where the drill will enter the wood and make a centering point in the wood. Place the MCB in the tailstock and adjust the depth of the forstner drill. Drill the hole at a maximum speed of 500 rpm. Make sure that the wood chips are unloaded in time. Place the tool rest parallel to the workpiece and run the support rod over the tool rest so that the drill cannot rotate in the tailstock. When the support rod comes to the wood, the hole is deep enough. Now make a notch in the wall of the hole, in which the mechahanism hooks engage. The notch should be 6mm wide and 2mm deep is enough. The Crown PMT is just the right size. If you place this tool against the bottom of the hole and pull it slightly to the left, you have already made the notch. Now cut off the “body” of the pepper mill, the head remains in the chuck. Drill a 19 mm hole in it (drill not included). Now use the drilled holes to clamp the workpiece in a centered position. So make sure that the edges are clean. Then make the outside shape.

Sharpen

The HSS chisels can be sharpened with a diamond file while the blades remain in the body. Sharpen both blades equally, so that the depth of the drilled holes remains the same. You can also sharpen on a grinder. If you take the knives out of the body, make sure that 1 knife cuts at the top and 1 at the bottom when replacing. The front blade protrudes 7.5 mm from the body, and the rear blade protrudes 10 mm from the body. Use a diamond file to sharpen the 25 mm forstner drill as it has carbide blades.

Tips

The drill that is mounted in the front of the MCB can also be replaced by another size. This drill is 25 mm but of course 35 mm is also possible. If the drill used only has a 8 mm holder.

Crushgrind Mini

The Mini is of course also Danish design. The quality is as we are used to from the grinders. They are made because the "regular" Crushgrinds was not a small and slim design. This criticism of the designers has now been tackled with the Mini. In the photo you can see the proportions well. On the left the Mini and on the right the "regular".

Technical

If you want to know the sizes of the holes to be drilled For the sizes, click here.